posted

On Monday, July 27, 2020

in

Blog

At the request of our customer, an agriculture equipment manufacturer, Advanced Heat Treat Corp. outsourced a salt spray test to a third-party vendor to provide our customer with completely non-biased results regarding our trademarked heat treatment UltraOx® and its corrosion resistance properties. Below are the parameters and results of the test:

Parts Included in the Salt Spray Test

- Three (3) UltraOx®'d cylinders; with nominal dimensions: 0.75”dia. x 1.18” length

- Three (3) UltraOx®'d cylinders; with nominal dimensions: 0.79”dia. x 1.83” length

The Salt Spray Method

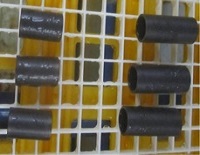

The samples were placed horizontal in the chamber, as seen below, and exposed for the duration of 300 hours, under the following ASTM B117-16 “Standard Practice for Operating Salt Spray (Fog) Apparatus” conditions:

- Test Media: 5% Salt Solution

- Cabinet Temperature: 95 to 96ºF

- Fog Collection Rate: 1.1 to 1.8 ml/hr

- Specific Gravity: 1.034 to 1.035

- pH Range: 6.6 to 6.8

- Tower Temperature: 112 -113 °F

- Pressure: 12 psi

The Salt Spray Results - Zero Rust After 300 Hours

| Initial |

168 Hours |

240 Hours |

300 Hours |

|

|

|

|

* UltraOx® passed the 300-hour salt spray test with zero rust!

If corrosion resistance is your priority, UltraOx® may be your perfect solution. Contact us today to see if UltraOx® is right for your application.

CONTACT US

*Results may vary based on material used, geometry of the part, etc. Contact an Advanced Heat Treat Corp. representative to discuss your application.

- agriculture

- corrosion resistance

- customer story

- firearms

- ultraox®