posted

On Wednesday, October 25, 2023

in

Blog

Ion/plasma nitriding, gas nitriding and nitrocarburizing are very complex thermochemical processes used for surface treating ferrous and titanium alloys components requiring enhanced tribological, bending fatigue and corrosion resistance properties [1-4]. Common materials include, but are not limited to: 316, 440, 17-4PH, Nitrallloy-135M, 4140, 4340, H10, P20, 718 and more.

Selective vs All-Over Nitriding

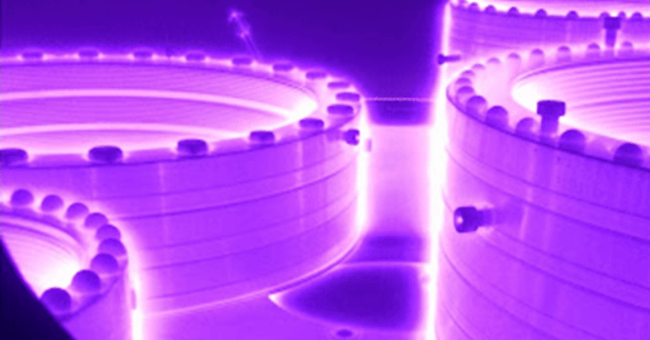

The ion/plasma nitriding process is realized in the vacuum vessel which serves itself as the anode and the cathodic heart plate/center used for loading the parts. The process has its benefits such as aggressive activation of stainless-steel parts as well as easiness of mechanical masking the threaded holes and other surfaces which must stay soft, see Figure 1.

Gas nitriding and nitrocarburizing (FNC) allows for all-over treatment of the parts. Advanced Heat Treat Corp.’s trademarked process, UltraOx®, allows for treatment of parts needing even higher wear and corrosion resistances, Figure 2.

Ion / Plasma Nitriding

Figure 1: Plasma/ion nitriding of steel rings. Picture taken at Advanced Heat Treat Corp. Monroe, Michigan. Note the bolts and balls masking the small-size holes not needing hardening.

|

UltraOx

Figure 2: UltraOx process on firearm parts. UltraOx provides three protective layers to protect parts from wear, abrasion and corrosion. It's widely used to replace chrome plating, QPQ and more.

|

Nitriding Benefit: Wear Resistance

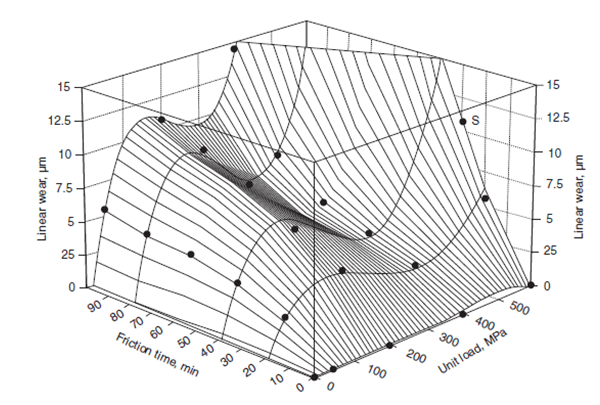

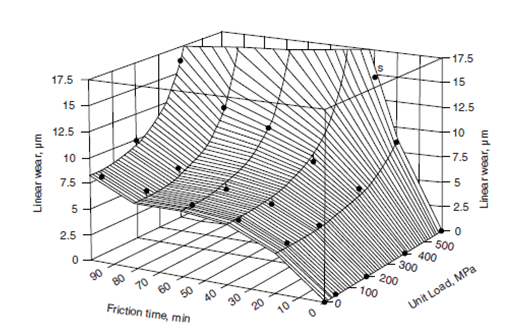

Well-controlled nitriding significantly enhances wear resistance and lowers coefficient of friction in many applications of steel components [1-2]. For certain steels, nitrided samples show even better tribological behavior than carburized samples of the same steels [3], see Figures 3 and 4.

It should be noted that a nitrided surface can endure wear under a severe contact stress/unit load up to 300 MPa.

Carburizing Carburizing

Figure 3: Linear wear vs. time of friction at different unit loads of carburized layer produced in 18HGT steel by gas carburizing at 930°C. Linear wear at 50 to 200 MPa was 5.4 to 10.8 µm, & wear intensity was 0.0375 to 0.083 µm/min. S-seizure. Adopted from [3].

Carburizing is available at AHT in Iowa only.

|

Nitriding Nitriding

Figure 4: Linear wear depth vs. time of friction at different unit loads of nitrided layer produced in 18HGT (0.18 wt.% C, 0.025 wt.% Si, 1.1wt.% Cr, 0.1 wt.% Ti) after nitriding at 530° C. Linear wear at 50 to 200 MPa was 5.8 to 11.6 µm and wear intensity was 0.024 to 0.072 µm/min. Adopted from [3].

Nitriding is available at AHT locations in Iowa, Michigan and Alabama.

|

Nitriding Benefit: Corrosion Resistance

UltraGlow and UltraOx nitriding processes developed by Advanced Heat Treat Corp allow for optimizing nitrogen and carbon content in the epsilon-type compound layer/white layer formed at the surface of treated component, which is so critical for increasing corrosion resistance of the surface. In addition, the UltraOx process not only significantly increases such resistance but also produces an attractive black color of the surface, visible even after the salt spray corrosion test, see Figure 5.

Test per ASTM

Figure 5: Mechanical components treated with UltraOx underwent a salt spray corrosion test for over 300 test hours at Advanced Heat Treat Corp in Waterloo, Iowa. The part on the left was the incoming/pre-treatment condition. Test per ASTM.

Chrome vs Nitriding vs Oxidized Steel

Figure 6: Anodic current density potential curves for chromium plated, nitrided and post oxidized steel samples tested in 5% salt solution, ph=4.0. Compound zone in nitrided layer was ε-type. Adopted from [9].

It was determined years ago that chromium plating increases corrosion resistance of plated steel but the nitriding techniques in combination with the post oxidizing steps provide even better results, see Figure 6.

Nitriding & Nitrocarburizing Services Offered at Three AHT Locations

All the above methods; nitriding both ion and gas, FNC and UltraOx are extensively applied by Advanced Heat Treat Corp. for treating many various types of parts from agriculture, aerospace, construction, automotive and other industries. We process them in our three nitriding locations in Waterloo, Iowa; Monroe, Michigan and Cullman, Alabama.

Interested in Learning More about Nitriding or Other Wear & Corrosion Resistance Solutions?

CONTACT US

References

1. E. Rolinski, “Plasma Assisted Nitriding and Nitrocarburizing of Steel and other Ferrous Alloys”, Chapter 11 in Thermochemical Surface Engineering of Steels, Ed. E. J. Mittemeijer and M. A. J. Somers, Pub. Woodhead Publishing, 2014, pp. 413-449.

2. D. Pye, “Practical Nitriding and Ferritic Nitrocarburizing”, ASM International, Materials Park, OH, 2003, 256 pp.

3. J. Senatorski, J. Tacikowski, E. Rolinski and S. Lampman, “Tribology of Nitrided and Nitrocarburized Steels”, ASM Handbook Vol 18, Friction, Lubrication and Wear Technology, ed. G. Totten ASM International, 2017, pp. 638-652.

4. H-J. Spies, “Corrosion behavior of nitrided, nitrocarburized and carburized steels”, Chapter 6 in Thermochemical Surface Engineering of Steels, Ed. E. J. Mittemeijer and M. A. J. Somers, Pub. Woodhead Publishing, 2014, pp. 267-309.

5. Standard Practice for Operating Salt Spray (Fog) Apparatus” published by the American Society for Testing and Materials (ASTM) B117.

6. H. -J. Spies, “Einfluᵦ des Gasnitrierens auf die Eigenschaften der Randschicht von Eisenwerkstoffen”, FREIBERGER FORSCHUNGSHEFTE, 1986, B 249, pp. 8-21.

- corrosion resistance

- edward rolinski

- ferritic nitrocarburizing

- gas nitriding

- ion nitriding

- nitriding

- nitrocarburizing

- plasma nitriding

- stainless steel

- ultraox®

- wear resistance