posted

On Wednesday, January 19, 2022

in

Blog

(Article originally published November 2021 and updated January 2022.)

What Makes Cryogenic Treatment Effective?

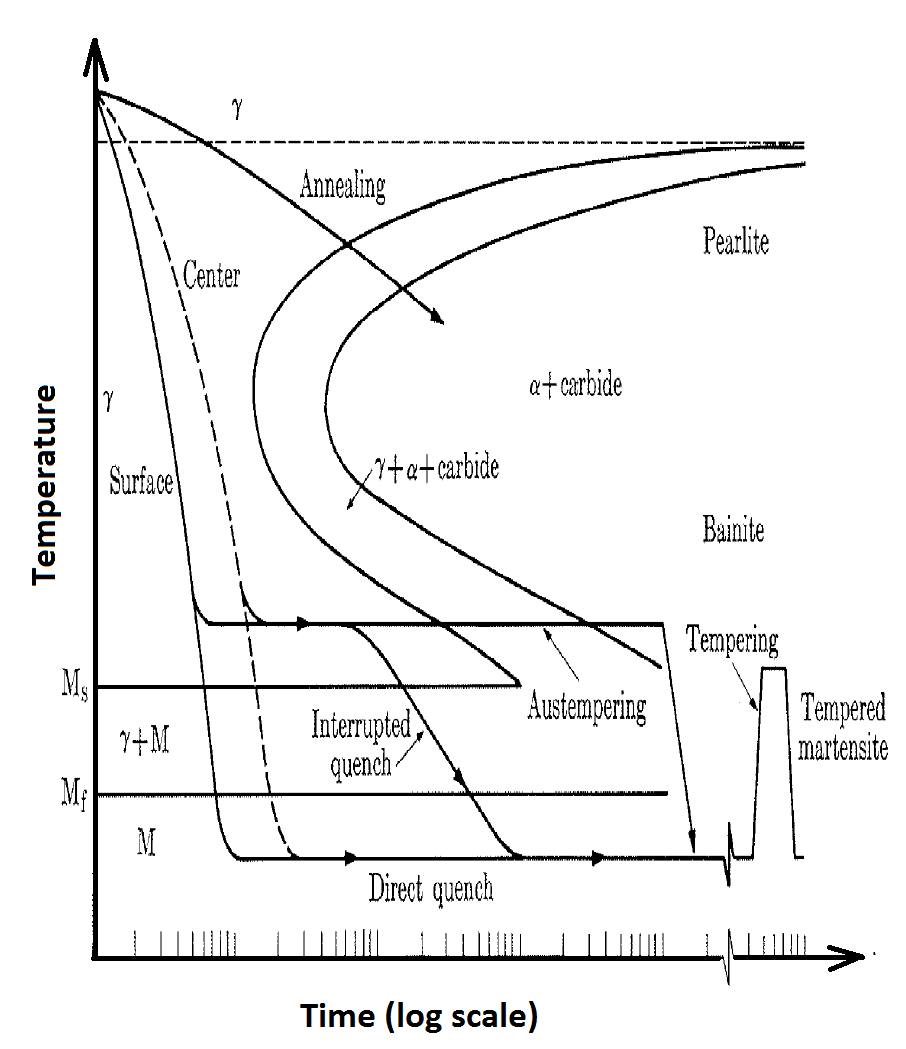

General heat treating of steels is essential for proper usage of those materials to the maximum of their technical capabilities. Steel properties such as hardness, tensile and yield strength, as well as ductility and fracture toughness can be formed as desired for various applications when proper heat treating is used. Even plain carbon steels with original structure of ferrite and cementite (carbide) can be quenched and tempered to form martensitic structure, which is known for its high hardness, see Fig. 1 and 2. This process is typically combined with the tempering or replaced with austempering, see Fig. 2. It should also be noted here that cooling rates for achieving 100% martensitic structure must be more rapid than the CRM (critical cooling rates to the left of this curve).

Fig. 1. Hardness of annealed iron-carbon alloy (α+carbide) and martensite versus carbon content. This difference in hardness is the reason for the quenching of steel. Adopted from [1].

Fig. 2. Transformation processes in carbon steels. Adopted from [1].

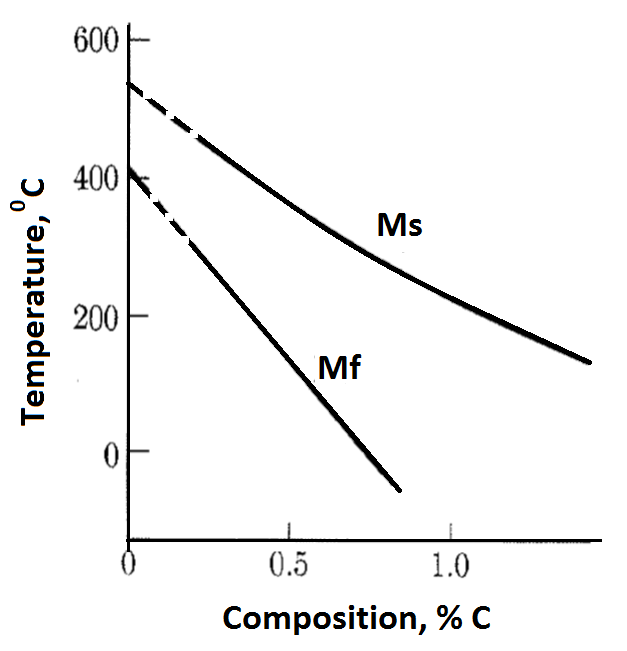

Obviously, heat treating processes are not limited only to the quenching. As-quenched structure must be tempered back to avoid too high stresses in the steel, or to eliminate retained austenite [1-3]. Very often, removal of the retained austenite is achieved with treatments at lower than room temperature since Mf temperature for higher carbon steels is below it [1, 2].

It should be noted that the starting transformation temperature of austenite into martensite Ms, as well as the final transformation temperature Mf depend on carbon content in the steel [1], Fig. 3.

Fig. 3. Effect of carbon on the starting, Ms and final Mf martensite temperatures formation in plain carbon steel. Adopted from [1].

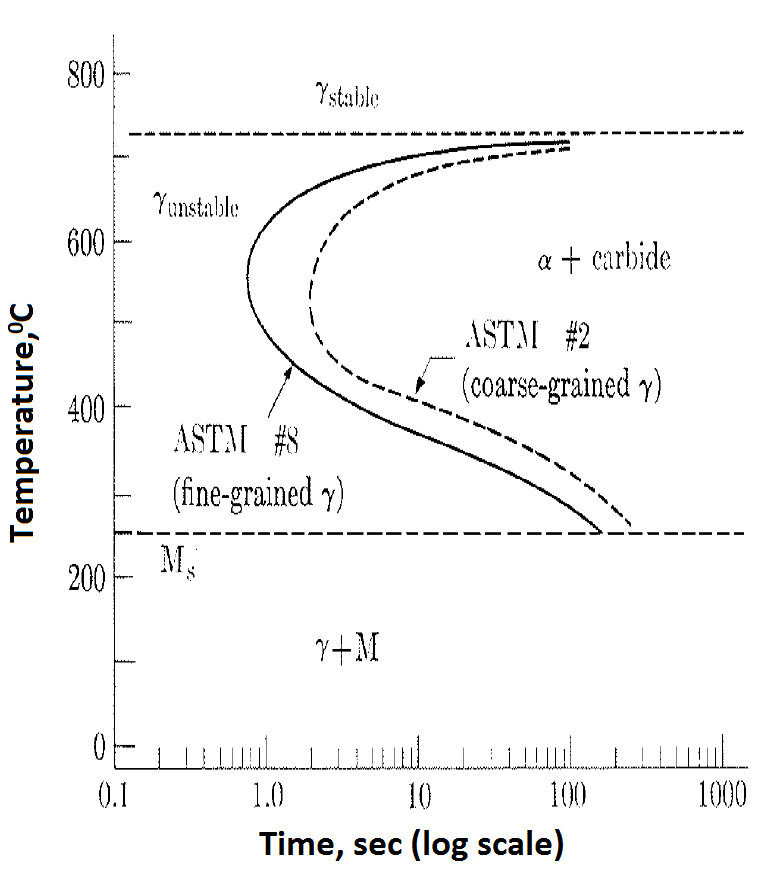

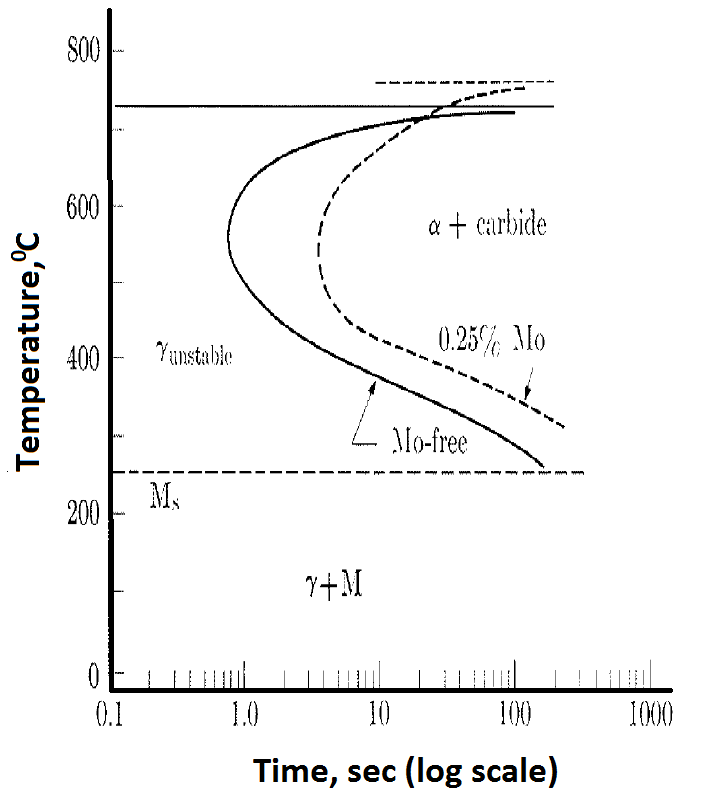

Critical cooling rate for transforming austenite depends also on grain size, as well as content of alloying elements in the steel, Fig. 4 and 5.

Fig. 4. The effect of grain size on the start of austenite decomposition for eutectoid steel. Adopted from [1].

Fig. 5. Effect of alloying elements in carbon steel on the start of transformation of austenite in carbon steel alloyed with molybdenum. Adopted from [1].

Cold Treatment

Cold treating of steel is widely accepted as an additional treatment for enhancing the transformation of austenite to martensite and to improve stress relief of castings and machined parts [2]. In common practice, -84 °C (-120 °F) is used as the optimal temperature for cold treatment.

Immediate cold treating after quenching offers the best opportunity for maximum transformation to martensite. However, the decision to use this treatment should be taken after analysis of the specific grade of steel and whether the product design will tolerate this type of treatment rather than tempering. In the majority of the situations, cold treating is done after tempering [2]. Typically, successful transformation during cold treating can be achieved easily when the temperature reaches -84 °C (-120 °F).

Deep Cryogenic Treatment (DCT)

Deep Cryogenic Treatment (DCT), also known as cryogenic processing, is a process which uses temperatures below -150 °C (-238 °F). The most common temperature used is the temperature of liquid nitrogen, -185° C (-300° F) [2].

The recent research reports show that DCT has a superior performance when coordinated with traditional heat treatment. For example, 30CrMnSi steel showed better impact toughness and strength were produced when DCT was used compared to quenching and tempering [3]. This was a result of refining of strip ferrite and lath martensite grains and also promoting the formation of the dispersed precipitation of stable carbides in the grain boundaries.

Subzero treatments used for completing martensitic transformations in tool and construction steels increases through-hardness of many mechanical components and tools to reduce their wear. The treatment is also used to control distortion of metal objects, modify vibrational characteristics of metals, increase fatigue life, reduce abrasive wear, and reduce electrical resistance [2].

Applications of Cryogenic Treatment Processing

Modern equipment for the dry cryogenic processes is computer controlled allowing to use a prescribed schedule and maintain at --185 °C (-300 °F) for a particular time before slowly returning the parts to room temperature [5]. Thermal shocks are eliminated since the material is not exposed to any cryogenic liquids.

Applications of cryogenic treatment are very broad. Materials with different compositions and different configurations can be chilled at the same time, even though each may have a different high temperature transformation point. Therefore, in situations where retained austenite could result in in excessive wear, the wear resistance for several different materials is improved, i.e., tool steels: high-carbon, martensitic stainless steels, and carburized alloy steels, cryogenic treatment can be used [4].

References

- L. H. Van Vlack, “Elements of Materials Science and Engineering”, Addison-Wesley Publishing Company, ISBN 0-201-08090-7.

- F. Dieckman, “Cold and Cryogenic Treatment of Steels”, ASM Handbook, Vol. IV Steel Heat Treating Fundamentals and Processes, ASM Heat Treating Society, 2013, pp. 362-386.

- Z. Weng, K. Gu, K. Wang, X. Liu and J. Wang, “The reinforcement role of deep cryogenic treatment on the strength and toughness of alloy steel”, Materials Science and Engineering: A, Vol. 772, 20 January 2020, 138698.

- cryogenics

- edward rolinski