posted

On Tuesday, May 2, 2023

in

Blog

The development of powdered metal (PM) technologies has been revolutionizing large volume manufacturing of mechanical components for a long time, as described in many publications of the American Society for Metals and Metal Powder Industries Federation [1,2]. Economic benefits from using sintered metal products have been systematically growing when the secondary operations, allowing enhancement of the surface properties of those products, have been modernized. In the early ’80s, recommended low-temperature thermochemical treatments of PM products were steam treating, gas nitriding and nitrocarburizing [1, 2]. However, the application of gas methods has been extremely limited and used only to >7.3 g/cm3 dense materials. At that time, it was noticed that during gas nitriding, ammonia penetrates too deeply into the low-density PM causing embrittlement of the treated component. There were attempts to overcome those limitations of gas nitriding with a high-temperature pre-oxidizing or steam treating before nitriding to block the internal structure of the component by forming oxides [3-6]. However, this was not a very successful solution because the higher temperature oxides may stay in the internal structure and lower temperature oxides required toughness properties of the product.

Introducing plasma/ion nitriding allowed for the elimination of the other processes’ negative side-effects by producing hard and uniform layers without any excessively deep penetration of the PM material by the nitrided layer [2-6].

Ion Nitriding & Nitrocarburizing Sintered Metal

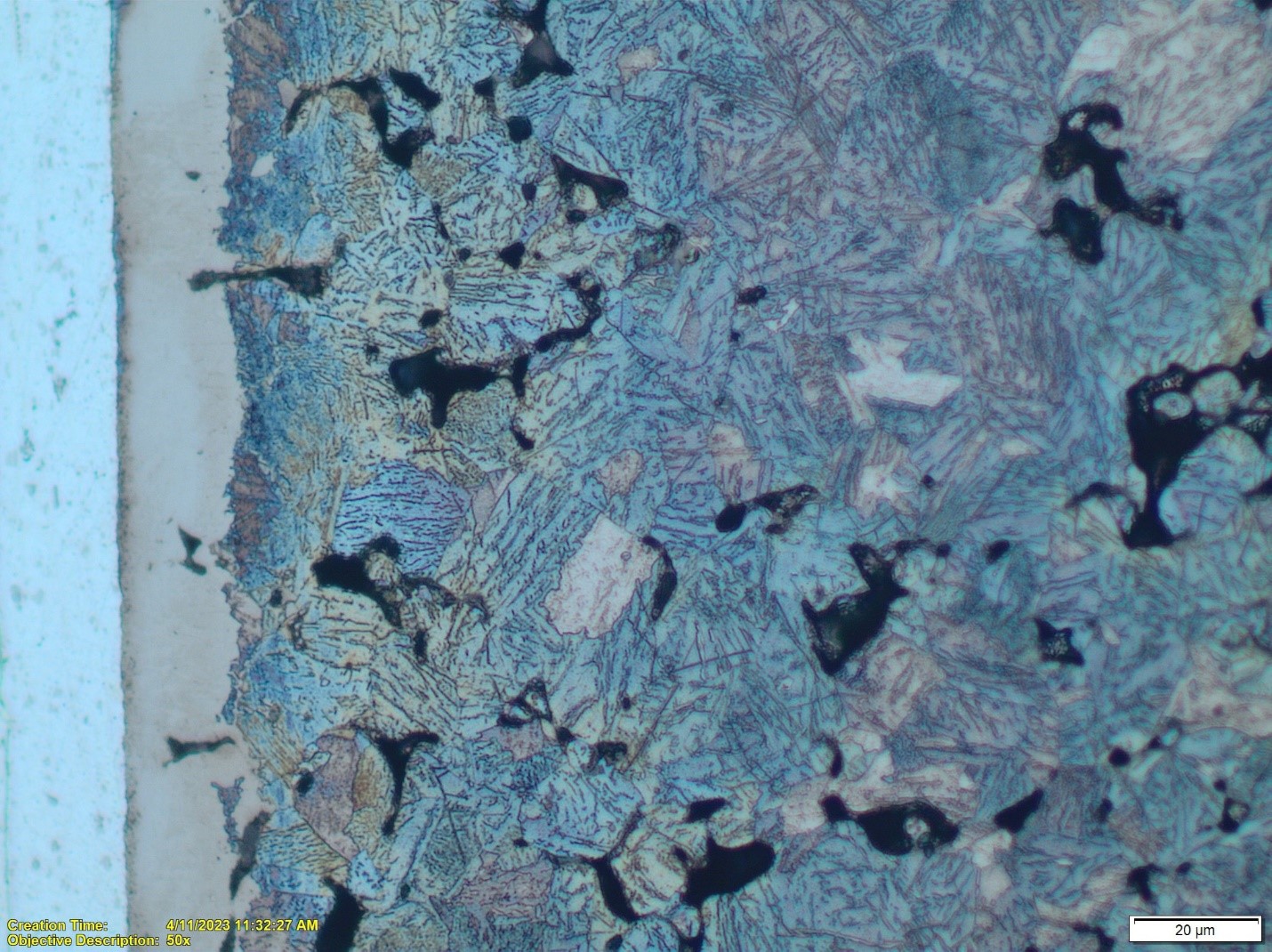

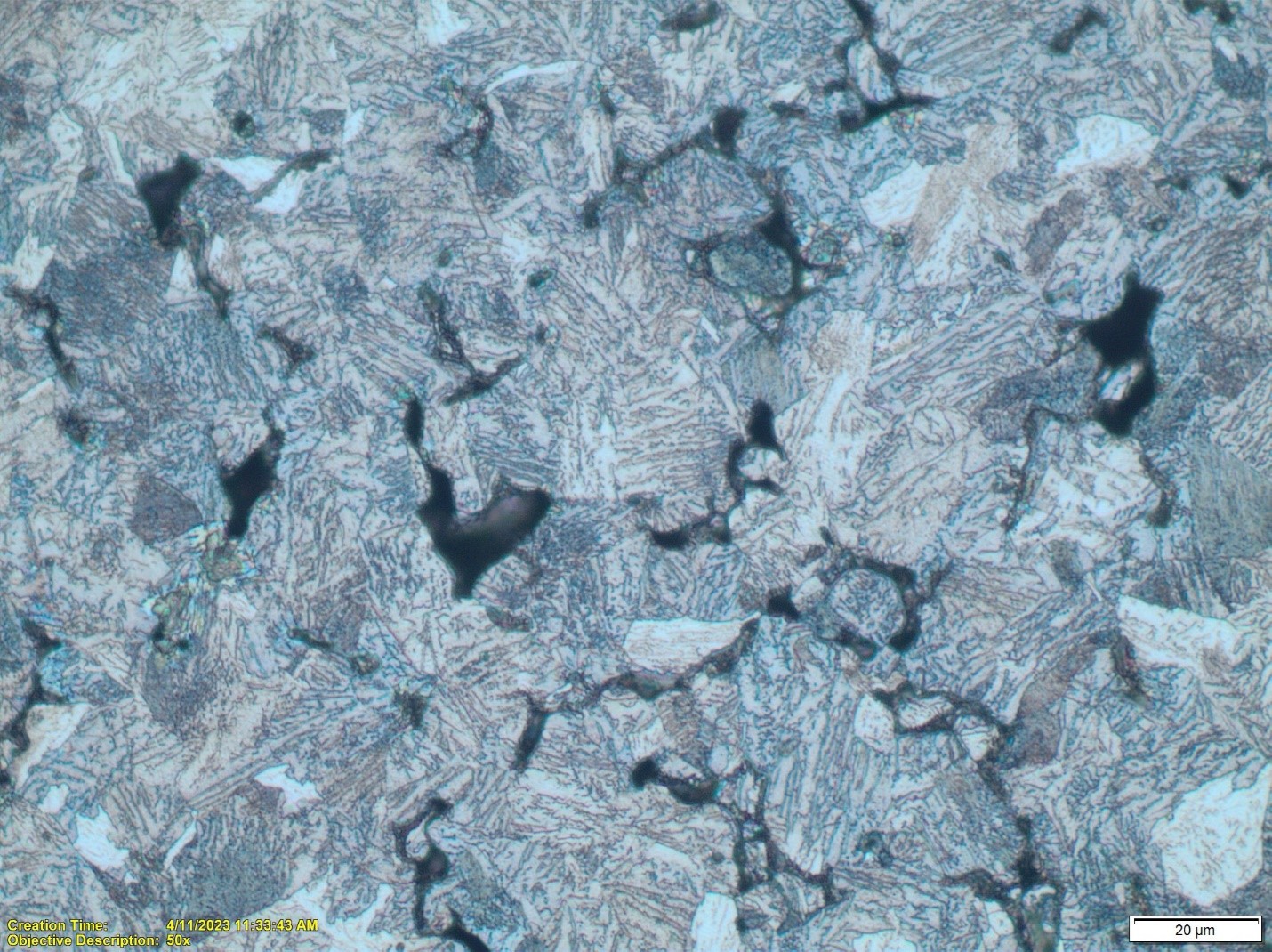

Figure 1 shows the near-surface and core structure of the 1/2" thick plasma/ion nitrided component. The photomicrographs of the 6.9 g/cm3 PM demonstrate all the positives of the plasma process. Note a solid compound layer (CZ) at the surface and the nitride-free core structure.

Surface After Ion Nitrocarburizing Surface After Ion Nitrocarburizing

|

Core After Ion Nitrocarburizing Core After Ion Nitrocarburizing

|

The drop-off test of the plasma nitrocarburized part carried out from the height of 40” (1 m) resulted in only minor damage of the part during its collision with the concrete floor.

Gas Nitriding & FNC Sintered Metal

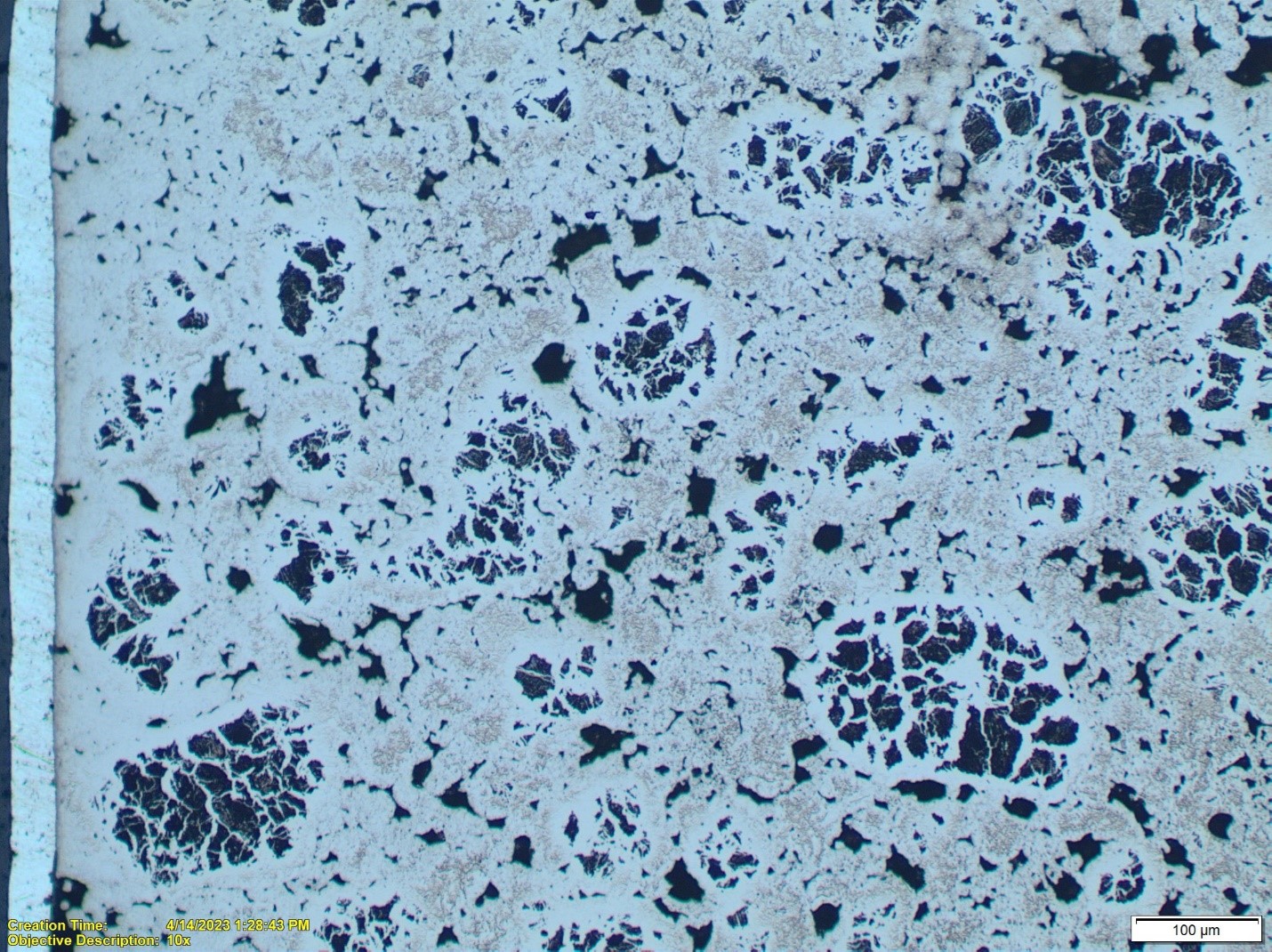

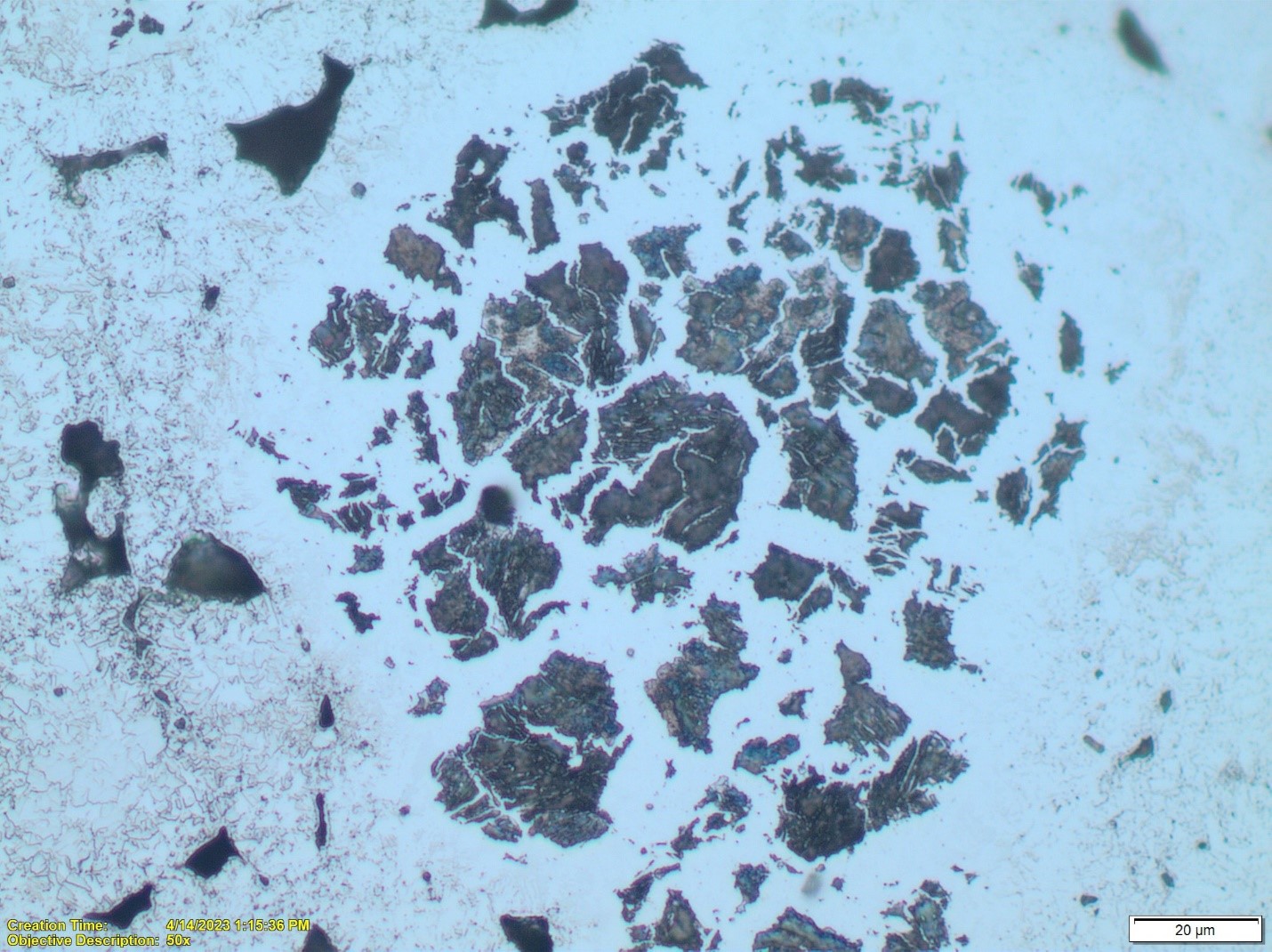

Gas nitriding and ferritic nitrocarburizing (FNC) have been used very successfully in many applications. However, in regards to the sintered metal/powder metal products, its usage has been very limited. The reason for that is demonstrated in Fig. 2 showing results of this treatment carried out on the same 1/2"-thick PM component with the 6.9 g/cm3 density. Note excessive presence of nitrides (white-etched precipitates) near surface as well as in the core of the sample.

Surface After Gas FNC Surface After Gas FNC

|

Core After Gas FNC Core After Gas FNC

|

The same drop-off test of the gas FNC-ed part carried out from the height of 40” (1 m) resulted in a complete disintegration and destruction of the part. This was direct proof that the processing caused its brittleness and very poor fracture toughness.

As demonstrated above, the plasma/ion nitriding process seems to be the best solution for forming nitrided layers in low-density PM [6-10]. This has been proven by Advanced Heat Treat Corp. many times.

Have Questions about Heat Treating Sintered Metal / Powder Metal?

CONTACT AHT

"Sintered Metal: Ion Nitriding vs Gas Nitriding" References

1. H. Boyer, “Secondary Operations Performed on P/M Parts and Products” in Metals Handbook Ninth Edition, Vol 7 Powder Metallurgy, American Society for Metals, 1984, 451-462.

2. D. Howard, “State of the PM Industry in North America-2021”, Proc. of the International Conference: PowderMet2021/AMPM2021/Tungsten 2021 Conference in Orlando, June 2021, Proc. ISBN No. 978-1-943694-27-3 © 2021 Metal Powder Industries Federation 105 College Road East, Princeton, New Jersey 08540-6692 USA, pp. 6-14.

3. H. Ferguson, “Steam Sealing for Nitrogen Treated Ferrous Part”, US Patent no 4,738,730, Apr. 19, 1988.

4. H. Ferguson, “The Heat Treatment of P/M Steels-an Overview”, Heat Treating Proc. of the 16th Conference, ASM, 1996, pp. 319-322.

5. 4. H. Ferguson, “Heat Treatment of Ferrous Powder Metallurgy Parts”, ASM Handbook, Volume 7, ASM, Materials Park OH, USA, 1998, pp. 645-655.

6. E. Rolinski,” Plasma Assisted Nitriding and Nitrocarburizing of Steel and other Ferrous Alloys”, Chapter 11 in Thermochemical Surface Engineering of Steels, Ed. E. J. Mittemeijer and M. A. J. Somers, Pub. Woodhead Publishing, 2014, pp 413-449.

7. E. Rolinski, G. Sharp, “Ion Nitriding and Nitrocarburizing of Sintered PM Parts”, Industrial Heating, Oct. 2004, pp 33-35.

8. E. Rolinski, G. Sharp, “When and Why Ion Nitriding/Nitrocarburizing Makes Good Sense”, Industrial Heating, Aug. 2005, pp 67-72.

9. E. Roliński, M. Woods “Plasma Nitriding Mechanisms of Low-Density Sintered Metal Products/Mechanismen des Plasmanitrierens von gesinterten Metallprodukten mit niedriger Dichte”, HTM J. Heat Treatm. Mat. 76 (2021) 1, pp. 58-63.

10. E. Rolinski, J. Ludeman, J. McCain, V. Popovski and M. Woods, “Nitriding Mechanisms of Ferrous Powder Metal Products in Gas, Salt and Plasma Methods”, Proc. of the International Conference: PowderMet 2021/AMPM 2021/Tungsten 2021 Conference in Orlando, June 2021, Proc. ISBN No. 978-1-943694-27-3 © 2021 Metal Powder Industries Federation 105 College Road East, Princeton, New Jersey 08540-6692 USA, pp. 330-337.

- edward rolinski

- ferritic nitrocarburizing

- gas nitriding

- ion nitriding

- nitriding

- nitrocarburizing

- plasma nitriding

- powder metal