posted

On Friday, August 8, 2025

in

Blog

Quenching is important to the integrity of many parts. However, with rapid cooling, the surface of a piece cools faster than the inside, which can cause small cracks on the surface. Magnetic Particle Inspection (MPI) is a great candidate for finding this kind of flaw in ferromagnetic materials, allowing for the adjustment of future heat treat runs.

How Does Magnetic Particle Inspection Work?

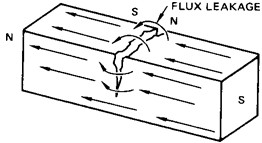

Every magnet has two poles. When a magnet is cut in half, each half has two poles as well. If a magnet is cracked (parallel to the poles), the faces of the crack will now also be poles. Magnetic field leaks out of the crack (known as “flux leakage”) and attracts magnetic particles, as long as the crack is near the surface.

Every magnet has two poles. When a magnet is cut in half, each half has two poles as well. If a magnet is cracked (parallel to the poles), the faces of the crack will now also be poles. Magnetic field leaks out of the crack (known as “flux leakage”) and attracts magnetic particles, as long as the crack is near the surface.

MPI hinges on magnetic field running through the surface of a test specimen. This can be achieved in multiple ways; however, the test specimen must be ferromagnetic. Most carbon and alloy steels are ferromagnetic, except for some stainless steel grades.

How Magnetism is Created

Direct Magnetization:

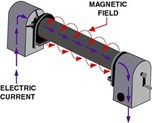

Running an electric current through a part creates a magnetic field, this is called direct magnetization. The magnetic field encircles the part around the volume that is electrified. An electric current can be transferred to the part by placing the part between two electrical contacts, or by placing electrical prods on the part and running current through a specific section.

Indirect Magnetization:

Placing a piece in a preexisting magnetic field is called indirect magnetization. This can be achieved in a few different ways. One way is to place permanent magnets on the part. This is low cost, but it lacks control of the magnetic field. Additionally strong magnets can be difficult to remove from the part.

Placing a piece in a preexisting magnetic field is called indirect magnetization. This can be achieved in a few different ways. One way is to place permanent magnets on the part. This is low cost, but it lacks control of the magnetic field. Additionally strong magnets can be difficult to remove from the part.

A more common alternative is to use an electromagnet called a “yoke”. A yoke usually looks like a heavy bar with ends with many joints, allowing for the flexibility to put the ends of the yoke on the sample piece. The yoke creates a magnetic field which is transferred to piece with contact.

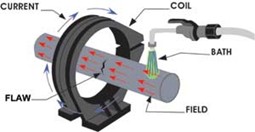

A longitudinal magnetic field can be achieved by placing the piece within a coil of wire or solenoid. The current running through the wire creates a magnetic field in the center of the coil, which the part can be placed within.

Types of Magnetic Particles: Visible, UV, Wet & Dry

Magnetic particles can be visible or ultraviolet light based. Iron filings (or similar) are coated with a thin layer of pigment so that they have high visibility against the sample piece. This pigment can be colored, red, black, white, etc. Alternatively, the pigment can be made to react under UV light, to glow in the dark. Visible light magnetic particles can be inspected under artificial or natural light. UV magnetic particles must be inspected under UV light and in darkness under 2 footcandles at the surface of the sample piece.

Additionally, magnetic particles can be wet or dry. Dry particles are simply dusted onto a sample, while wet particles are suspended in liquid and sprayed on. Particles made to be in liquid are smaller than those made to be dry, giving better resolution for the test. However, these smaller particles are more easily caught if a surface is rough, creating more “noise” in the results. Using dry or wet particles depends on the application. Less commonly, magnetic rubber can be used for inspection. An uncured rubber with magnetic particles mixed in is left to cure in a hard-to-reach area (inside diameter gear teeth etc.) while under a magnetic field. Once cured, the rubber can be extracted, and the particles will be trapped in the mold and show where the indications are.

Why Use MPI for Your Heat Treated Parts?

Why Use MPI for Your Heat Treated Parts?

MPI is a non-destructive evaluation technique with lower associated costs than many other techniques. MPI is common with certain part geometries, but it can be adapted to many different shapes and sizes. It doesn’t require as pristine surface condition or dwell times of penetrant techniques.

At AHT, MPI serves as a crucial quality assurance step by revealing surface or near-surface flaws, making it an important tool used extensively with induction hardening jobs along with carburizing, through hardening, etc. AHT also provides MPI as a standalone service when customers require non-destructive testing (NDT).

AHT has multiple certified MPI inspectors on staff – both Level I and Level II – certified in accordance to SNT-TC-1A. Should you have any questions, please feel free to contact us.

CONTACT US

Article author: Ellie Wilkes, Summer 2025 Engineering Intern

Sources:

[1] https://www.nde-ed.org/NDETechniques/MagParticle/index.xhtml

[2] https://www.nde-ed.org/Physics/Magnetism/index.xhtml

- burton

- induction hardening