Carburizing and Cryogenic Treatment: How They Work Together

Carburizing and cryogenic treatment are frequently paired heat treatment processes used to improve the performance and reliability of steel components. When properly applied, they create a hard, wear-resistant surface while maintaining a softer, more ductile core and long-term dimensional stability.

These processes are commonly specified for gears, shafts, pins, bearings, and aerospace components where surface durability and fatigue resistance are critical. Understanding how carburizing and cryogenic treatment work (and when they add value) helps engineers and manufacturers select the right heat treatment strategy.

Please Note: Carburizing and cryogenic treatment are offered at our Burton Ave. location in Waterloo, Iowa only.

Carburizing: Creating a Hard Wear-Resistant Surface With A Softer Ductile Core

The goal of carburization (a type of case hardening) is to have a hard, wear resistant surface layer but a softer, more ductile core. When quenching steels, the maximum achievable hardness is directly proportional to the carbon content within the steel (i.e. the higher the carbon content the higher attainable hardness).

By diffusing carbon into the surface, the surface can be significantly harder than the core. Here at Advanced Heat Treat (AHT) (Burton Ave facility only), gaseous carburizing and subsequent quenching are primary treatments that we provide to our customers.

During carburizing treatment, the steel parts are heated to a temperature above the upper critical temperature of the steel, causing the steel atoms to transform into a different arrangement (phase), called austenite. This principle is key in allowing carbon to diffuse into the surface of the steel. The diffusion rate of carbon into the steel mainly depends on time, temperature, and carbon potential in the atmosphere.

Once the diffusion portion of the process is complete, the steel parts are then cooled rapidly in an oil quench in which they transform into a much harder phase, martensite. When quenching, the surface cools faster than the bulk, causing high-carbon martensite to form at the surface, while low-carbon martensite or other softer phases/microstructures form in the core material. The resultant microstructure in the core depends on the size or thickness of the material, the steel alloy, and the quench rate. In the as-quenched condition, the parts are in their highest hardness state, and the microstructure is highly stressed.

After quenching, the steel parts are then tempered; it is brought to a temperature just high enough for the material to “relax”, which causes a reduction in hardness. Tempering allows us to target a specific surface hardness needed (usually specified in a range). The tempering temperature is inversely proportional to the resultant hardness (i.e. the higher the tempering temp, the lower the surface hardness).

The Transformation from Austenite to Martensite

To achieve martensite, the steel must be cooled sufficiently fast. Depending on the heat treat practices, steel alloy, amount of carbon in the diffusion layer, or size/thickness of the parts, sometimes not all the austenite is converted into martensite. Martensite formation doesn’t depend on diffusion; it is an athermal transformation.

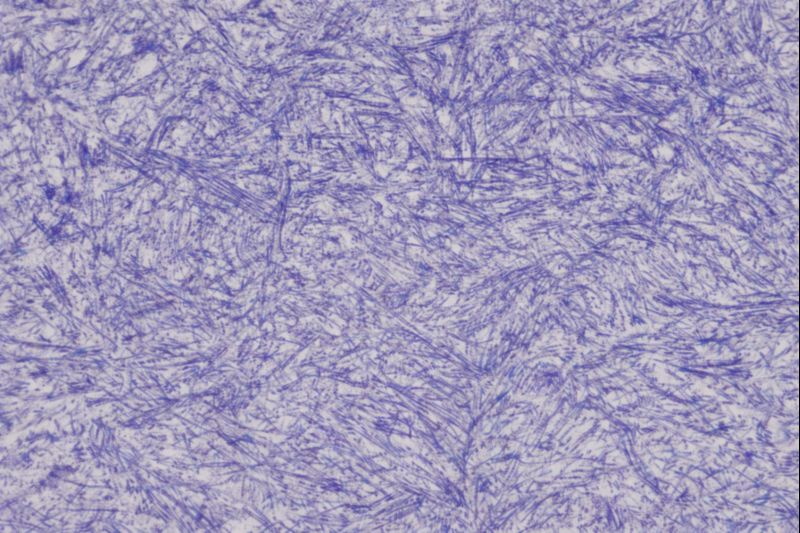

The transformation from austenite to martensite is not based on time at a certain temperature, but rather the final temperature reached. The only way to transform more austenite to martensite is to keep cooling to lower temperatures. Because of this, there can be a higher than desired amounts of retained austenite in the case after the initial quench. This is a problem for two reasons. First, austenite is ductile, making steel less hard overall. Additionally, these ductile regions make chipping of the case a big issue. Second, austenite is not stable at room temperature, only high temperature, and over time (and stress), some of the austenite will transform into other phases. Since different phases don’t have the same density, portions of the part will change size with transformation, causing distortion and/or stress in the part. Cryogenic treatment aids in the transformation from retained austenite to martensite after quenching and thus helping these associated issues to be remedied. (Pictured: Microstructure of Cryogenic 9310 at 1000X)

How Cryogenic Treatment Improves Performance

When a part is cryogenically treated, it is placed in a cryogenic chamber after the initial quench. Cryogenic chambers can reach down to -300Fo, but often -90Fo to -110Fo is sufficient. These lower temperatures force more of the retained austinite to transform into martensite. This eliminates dimensional instability down the line and creates a more uniformly hard case (outer layer). Note, that the material must still be tempered to gain toughness after this continued quench, just as with more conventional oil quenches.

What Gets Carburized & Cryogenically Treated?

Carburizing and cryogenic treatment are most commonly applied to low-carbon and low-alloy steels designed for case hardening (pictured). At Advanced Heat Treat Corp., frequently processed grades include SAE 8620, SAE 9310, SAE 1018, and SAE 1117.

8620 is commonly used in many different industries for gears, pins, shafts, and more and is highly recommended by AHT as a top material to use when Carburizing. 9310 is more of an aerospace grade of steel and parts are often cryogenically treated in addition to carburization because of the tight tolerance on dimensions of many parts.

At AHT, we can cryogenically treat any steel to gain additional dimensional stability, martensite percentage, and case performance. Not all materials require a cryo-treatment, so feel free to reach out to AHT to determine if this process is suggested.

AHT provides gaseous carburizing and cryogenic treatment services for manufacturers across a wide range of industries. Our metallurgical team works closely with customers to determine the most effective heat treatment strategy for each application, balancing hardness, toughness, wear resistance, and dimensional stability.

If you have questions about carburizing, cryogenic treatment, or material selection, contact Advanced Heat Treat Corp. to discuss your application.

REQUEST QUOTE

Written by Ellie Wilkes (summer 2025 intern) and Nick Lewis (AHT lab supervisor)

Frequently Asked Questions About Carburizing and Cryogenic Treatment

What is carburizing?

Carburizing is a heat treatment process that increases surface carbon content to create a hard, wear-resistant case while maintaining a tough, ductile core.

What is cryogenic treatment?

Cryogenic treatment is a post-quench process that cools steel to sub-zero temperatures to transform retained austenite into martensite, improving hardness consistency and dimensional stability.

Why is cryogenic treatment used after carburizing?

Cryogenic treatment reduces retained austenite in carburized cases, helping prevent chipping, dimensional changes, and delayed distortion during service.

Does cryogenic treatment replace tempering?

No. Cryogenic treatment does not replace tempering. Parts must still be tempered after cryogenic processing to reduce brittleness and achieve the proper balance of hardness and toughness.

What steels are commonly carburized and cryogenically treated?

Common steels include:

- SAE 8620

- SAE 9310

- SAE 1018

- SAE 1117

Can any steel be cryogenically treated?

Most steels can be cryogenically treated, but not every application requires it. The need for cryogenic treatment depends on alloy selection, part geometry, tolerance requirements, and service conditions.

References

- Boyer, Howard E. Practical Heat Treating. American Society for Metals, 1989. ISBN 0-87170-178-2, chapter 10.

- Jurci, P.; Dlouhý, I. Cryogenic Treatment of Martensitic Steels: Microstructural Fundamentals and Implications for Mechanical Properties and Wear and Corrosion Performance. Materials 2024, 17, 548. https://doi.org/10.3390/ma17030548

- MacKenzie, D. Scott. “The Meta-Stable Microstructure of Martensite.” Gear Solutions Magazine, 15 Jan. 2025, https://gearsolutions.com/departments/hot-seat/the-meta-stable-microstructure-of-martensite/

- Bengtsson, Sven, et al. “Carburizing of Low-Alloyed Chromium Materials – An Overview.” Hognas, 9 June 2018, https://www.hoganas.com/globalassets/downloads/technical-papers/pm/carburizingoflowalloyedchromiummaterials.pdf

- Mostafa El Laithy, Ling Wang, Terry J. Harvey, Bernd Vierneusel, Martin Correns, Toni Blass, Further understanding of rolling contact fatigue in rolling element bearings - A review, Tribology International, Volume 140, 2019, 105849, ISSN 0301-679X, https://doi.org/10.1016/j.triboint.2019.105849

- K. Sugimoto, M. Mukherjee, 8 - TRIP aided and complex phase steels**Every effort has been made to trace copyright holders and to obtain their permission for the use of copyright material. The publisher apologizes for any errors or omissions in the acknowledgements printed in this book and would be grateful if notified of any corrections that should be incorporated in future reprints or editions., Editor(s): Radhakanta Rana, Shiv Brat Singh, Automotive Steels, Woodhead Publishing, 2017, Pages 217-257, ISBN 9780081006382, https://doi.org/10.1016/B978-0-08-100638-2.00008-0.