Heat Treatment for Aerospace & Defense

Heat treatment plays a crucial role in the aerospace industries as it allows for the optimization of material properties, enhances component performance, and ensures the reliability and safety of critical aerospace systems. At Advanced Heat Treat Corp. (AHT), we’ve worked with aerospace customers for over 40 years, providing a variety of heat treat services such as ion nitriding, gas nitriding, UltraOx, carburizing and more. Our commitment to quality and technical expertise make us a great partner and trusted resource.

*Conventional heat treatments such as carburizing, induction hardening, etc. are NOT Nadcap accredited at AHT. Please contact AHT for details.

Nadcap Accredited in Nitriding for Over a Decade

AHT earned its first Nadcap accreditation for ion nitriding at its corporate headquarters and service center in Waterloo, Iowa in 2013. Since then, AHT has also added gas nitriding and nitrocarburizing to its scope and earned Merit Status. Learn more about our Nadcap accreditation by reading past articles, press releases & more by clicking here.

.png)

AMS Specifications

AHT can comply with the following AMS specifications:

- AMS 2757 - Gas Nitrocarburizing

- AMS 2759/6 - Gas Nitriding

- AMS 2759/8 - Ion Nitriding

- AMS 2759/10 - Gas Nitriding

- AMS 2759/12 - Gas Nitrocarburizing

Aerospace Customer Specifications

( View Advanced Heat Treat Corp.'s certifications on our Quality webpage by clicking here. )

( View Advanced Heat Treat Corp.'s certifications on our Quality webpage by clicking here. )

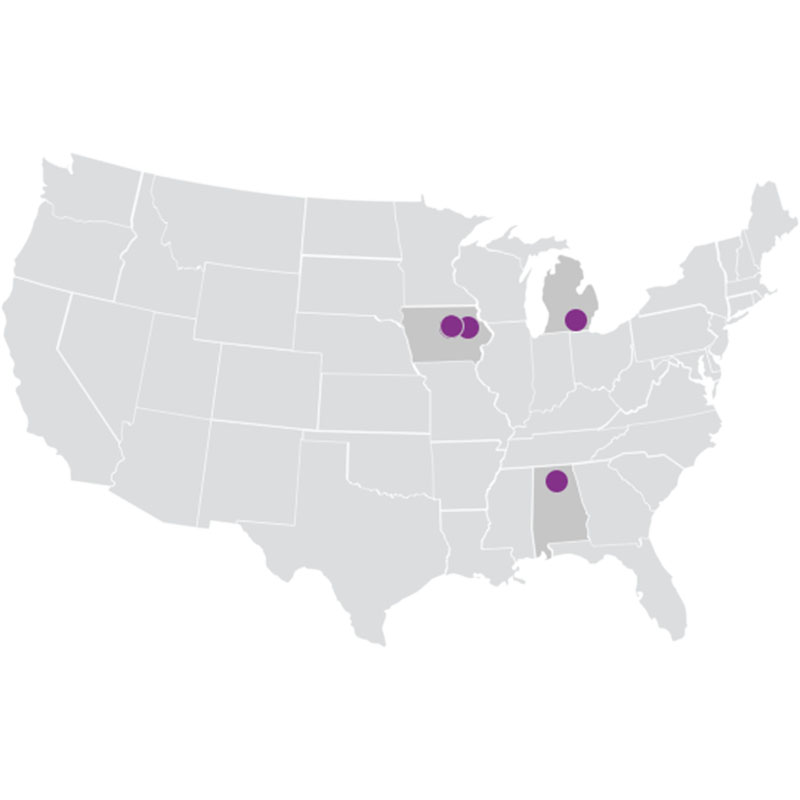

Four AHT Heat Treat Locations Serving the Aerospace & Defense Industries

Four AHT Heat Treat Locations Serving the Aerospace & Defense Industries

Aside from our Nadcap facility (located at 2825 MidPort Blvd. Waterloo, Iowa), we also have three other locations that can accommodate aerospace and defense fixturing, tooling, dies, etc. not requiring Nadcap.

Additional Facilities include:

- Iowa: 2839 Burton Ave, Waterloo, Iowa 50703

- Alabama: 1545 County Road 222, Cullman, Alabama 35057

- Michigan: 1625 Rose Street, Monroe, Michigan 48162

REQUEST A QUOTE

Heat Treated Aerospace Applications

While this is not an exhaustive list, here are few aerospace parts we've heat treated:

- Worm Shaft Slugs

- Air Shrouds

- Adaptor Plates

- Die Blocks

- Screws

- Pistons

- Spline Shafts

|

- Coupling Hubs

- Coupling Adaptors

- Coupling Splines

- Bearing Sleeves

- Bearing Races

- Drive Shaft

- Pins

|

- Spools

- Sprockets

- Sockets

- Brackets

- Flappers

- Pump Shafts

- Cylinder Blocks

|

- Bushings

- Barrels

- Bars

- Bolts

- Gears

- Rings

- Pump Shafts

|

Other Related Aerospace Heat Treatment Content

Ion Nitriding of Titanium Aerospace & Armament Applications

Ion Nitriding of Titanium Aerospace & Armament Applications

VIEW ARTICLE