Forging materials contain an elevated amount of nitride-forming elements such as chromium, vanadium, and molybdenum.

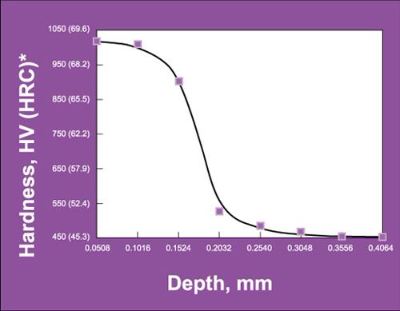

These types of nitrides have excellent thermal stability up to 1100°F. They increase hardness and abrasion resistance of the tool after nitriding without significantly reducing its impact properties. Such tools after UltraGlow® Ion Nitriding can have a very high hardness if required (i.e. up to 70 HRC equivalent) as shown below.

Hardness Profile in H-13 forging tools. *Equivalent HRC, typical

Heat Treated Forging Die Examples

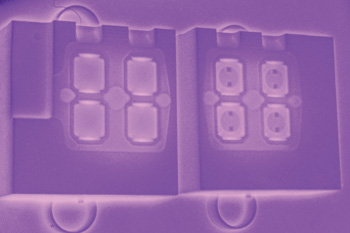

Forging die during UltraGlow® Ion Nitriding

|

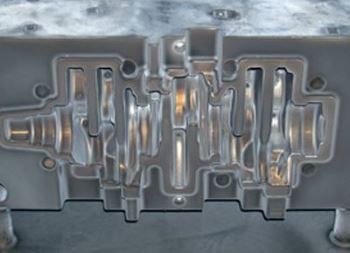

Forging die after UltraGlow® Ion Nitriding

|

Benefits of Nitriding Forging Tools

- High hardness (up to 70 HRC equivalent)

- Excellent abrasion resistance properties

- Corrosion resistance

- View more information on UltraGlow Ion Nitriding by clicking here

Request a Quote for Your Forging Tools.

Fill out RFQ Form